Corrugated Boxes Quality Tests

Corrugated Boxes Quality Tests https://bloompack.com/wp-content/uploads/2022/03/Corrugated-Boxes-Quality-Tests.jpg 1000 1000 BloomPack //bloompack.com/wp-content/uploads/2024/05/BLoomPack-New-Logo.png

1. Bursting Strength Test

This test use to know the carton resistance, thickness and the quality of boxes, the ideal weight the box can afford. If you have overweight inside or outside the box, the test shown this clearly. It is also known as the Mullen test.

Bursting factor = Bursting strength (kg/cm2) x 1000/Grammage (gm/m2)

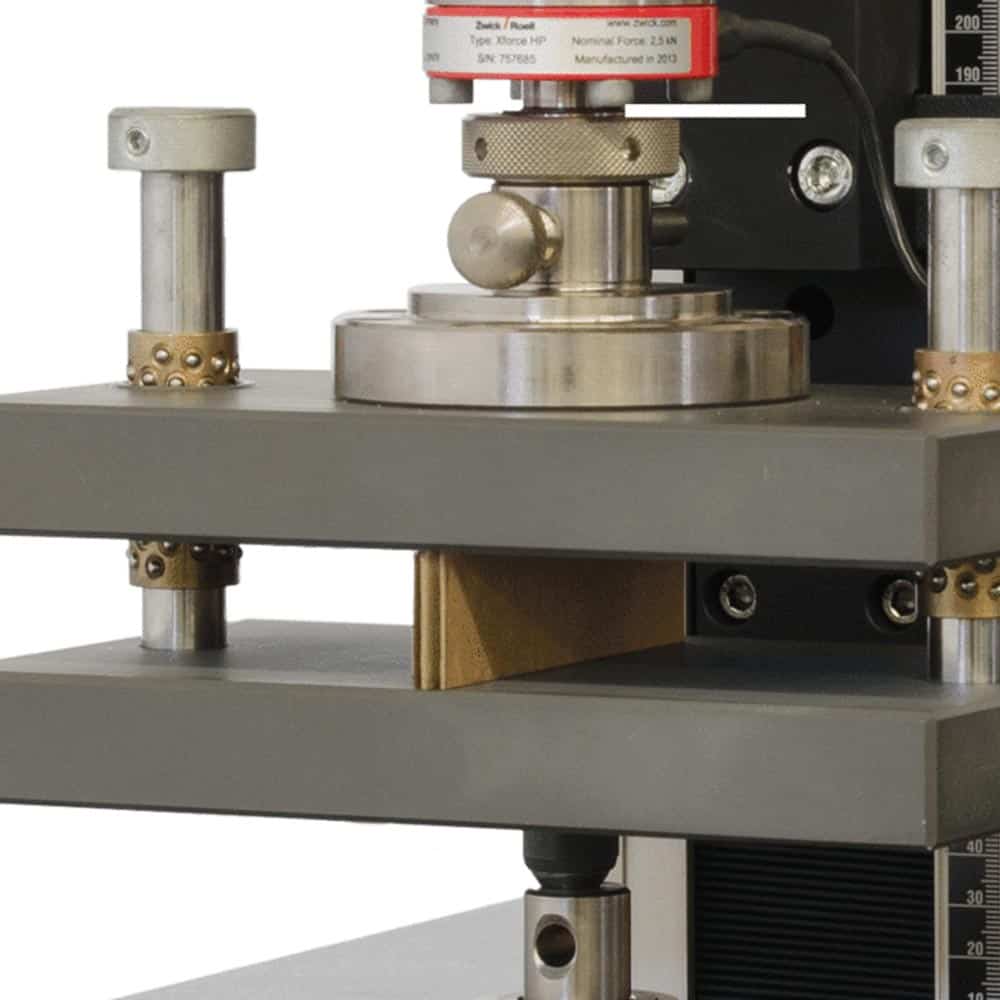

2. Edge Crush Test

The edge is responsible for the strength of the box. The weight force concentrated on these edges. After retail, usage boxes several times in addition to the transportation, they may be destroyed. In the Edge Crush test, force is applied to one side of the box, perpendicular to the ridges, until the box gets crushed.

3. Water Resistance of the Gluing

The corrugated box needs to use tapes to close in the ordinary types, so it is exposed to the different weather all the year. The different climate affected on the glue lines. Test is corrugated board is immersed in water while exposing the glue lines to check for bond strength and water absorption.

4. Cobb Sizing Tester

To test the quality of the box, Firstly, the box is impressed on the water, and then the water is squeezed out of the sample using pressure. As a result you can calculate the Cobb value as the result to the difference in the weight as result to the retained water. The lower the Cobb value the better the water resistance.

5. Paper Grammage and Thickness

To test box quality and rigidity, when more padding is required, a box with a higher thickness is used. Thin boards with dense flutes have a high grammage. Such boxes are needed when the packaging should be more compact and rigid.

6. Puncture Resistance

To test cardboard strength during transportation, Puncture resistance tests how well the box can handle the impact made with a pyramid or triangularly shaped weight.

7. Scuff Resistance Test

Very important test to ensure the printing on the box can sustain rubbing.

8. Box Compression Test

Test to the boxes on different orientation and the quantity is carried on the box. Through the McKee formula where the Edge Crush Test (ECT), Caliper or corrugated board thickness (CBT) and box perimeter (P) values are considered.

9. Chemical Analysis

To check the product formulation and the quality of the box through the microscopic examination and some specific chemical examination.