Flexographic Printing

Flexographic Printing https://bloompack.com/wp-content/uploads/2022/03/Flexographic-printing.jpg 1920 1212 BloomPack //bloompack.com/wp-content/uploads/2024/05/BLoomPack-New-Logo.png

Printing on corrugated boxes has different types. Consumption of large numbers increases all time. Cartons have multiple benefits such as reusing many times in different ways, being eco-friendly, recycling, providing a comfortable zone to the product inside, and having multicolor to express and help in product branding.

Flexography is a printing technique type that replaces a rubber sheet with a flexible printing plate. Plate of ink contains ink that rotates at high speed and transfers the design on the material through holes on anilox rolls. Also, different printing plates are available for each color.

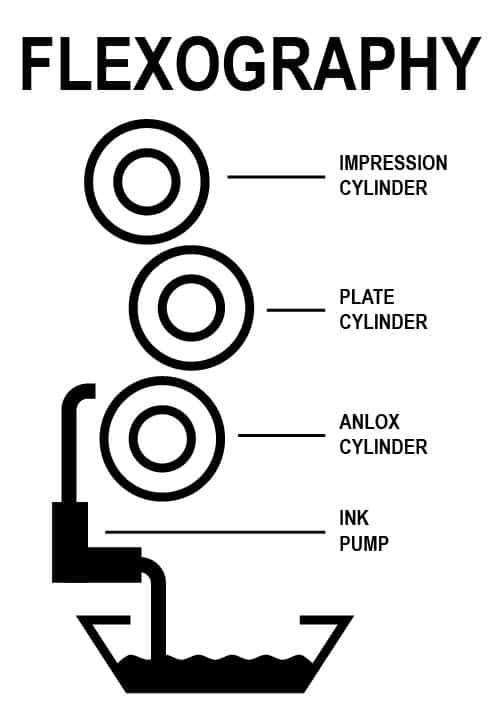

Flexographic Printing consists of several rollers:

- Anilox roller

- Plate cylinder

- Impression cylinder

Bumps feeds anilox roller with ink then transfers ink to the plate cylinder that contains a flexible printing plate. The material on which the printing will be made placed between the plate and the impression cylinder, now you are ready to start printing.

You can use various materials such as paper, fabric, plastic film, or corrugated cardboard.

Benefits from the Flexographic Printing

- The whole printing technique is automatic, from A to Z

- Flexography causes low-cost material; it is cost-efficient compared to other printing methods

- Flexography printing saves your time because you can finish a large quantity of work very fast

But all benefits logically meet some disadvantages like high price in low quantities; Also printing setup system consuming much time.